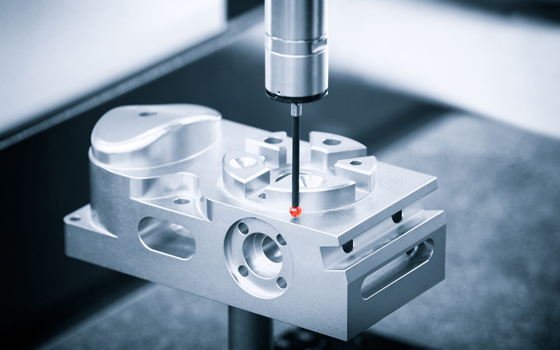

CMM

A Coordinate Measuring Machine (CMM) is a tool that can measure the dimensions of a machine/tool parts using coordinate technology. The dimensions include the height, width and depth in the X, Y, and Z axis. A common use of CMMs is in manufacturing and assembly processes to test a part or assembly against the design intent. A coordinate measuring machine is used to measure parts, prototypes, and check dimensions against a blueprint or CAD. They typically measure products that companies manufacture and document their specifications.

Coordinated measuring machines, often referred to as CMMs, are valuable tools in the field of metrology. These highly sophisticated machines enable precise and accurate measurement of complex objects, making them indispensable in various industries such as manufacturing, aerospace, and automotive. With their ability to measure the geometrical features of an object, CMMs play a crucial role in quality control and assurance processes.